WH

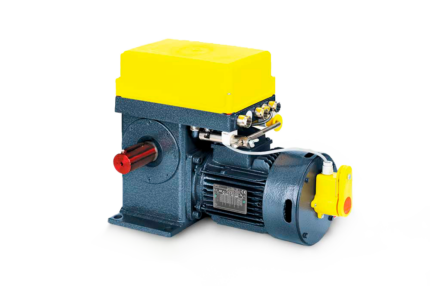

The operator:

Self-Locking worm-wheel operator with integrated brake system. Two shafts with free ends. The limit switch shaft with its own drive worm is integrated in the gear box and runs in oil.

The worm-wheel of special bronze and worm are equipped with ball bearings for noiseless operation. It has standard a range of 33 rotations of the main shaft.

The AC motor is directly with standard voltage 3-phase AC 230/400 V. (special voltage at options). All protruding shaft ends are sealed against oil leakage, so the unit can be mounted in any position: the horizontal position is recommended.

The control box:

The control box is mounted on the drive section and is built according to VDE guidelines.

Control voltage 24 V. Auxiliary push buttons open – close for operation during mounting. Possibility of connection of remote controls of any kind, safety rail control, photocells etc. Auxiliary push buttons open – close for operation during mounting. The operator can also be equipped with a limit switch system ES10. The limit circuit then consists of a potential-free limit switch, a control current limit switch for determining the end positions and a safety switch for each direction of rotation.

The standard version also includes an emergency crank with electric emergency crank protection.

The Emergency chain operation

This can be either lateral to the drive (KNG) or positioned at the front of the motor (RKG).

Both for horizontal or vertical mounting. It is operated by means of a reel chain. Switching on and off of the braking system is by means of a separate chain. The integrated security switch avoids that the engine starts during the emergency operation. During the use of the emergency unit the end positions continue preserve.

Maintenance:

The drives are maintenance-free. Lifetime lubrication makes every oil change unnecessary. Adjusting the brake is basically not necessary.

GM

Worm-wheel operator Type GM 1200-2650

The operator:

Gear box with irreversible worm and worm-wheel. Two shafts with free ends, the wormwheel of special bronze and worm are equipped with ball bearings for noiseless operation. The worm-wheel of special bronze and worm are equipped with ball bearings for noiseless operation. The standard version has 30 revolutions at the drive shaft. The AC motor is directly with standard voltage 3-phase AC 230/400 V. (special voltage at options). All protruding shaft ends are sealed against oil leakage, so the unit can be mounted in any position: the horizontal position is recommended.

The limit switch

On the reduction is a box mounted with limit switch ES10, this can be connected with a separate controller which can be chosen out of the LST/WST range. The limit switch consist out of a potential free switch, a control current limit switch for the end positions and a safety switch for each side of rotation.

The Emergency chain operation

The RKG is mounted in front of the engine for a horizontal or vertical placement. Only one chain for manual operation. The integrated security switch avoids that the engine starts during the emergency operation. During the use of the emergency unit the end positions continue preserve.

FV

Safety bearing Type FV 20/35 E – 360 E

The safety bearings FV 20/35 E to FV 360 E have been tested and approved by the TÜV SÜD Industry Service and got because of those tests also corresponding certificate numbers. They correspond to the European Standards DIN EN 12604 / DIN EN 12605 (edition Aug. 2000 ) and GS – BE – 04 (edition Jan.2001). TÜV-certificates are on request available. All types are equipped with a damping system, witch absorbs the blocking moments considerably. The standard safety bearings have also an electric circuit breaker and in option there is a water protected version. The safety bearing can not be placed on the same side as the traction or motor!

ROLLER DOORS

ROLLER DOORS ACCESSORIES

ACCESSORIES