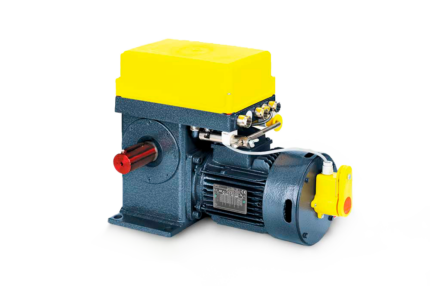

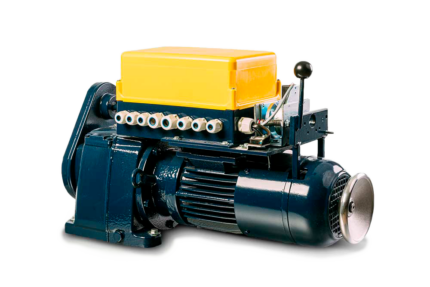

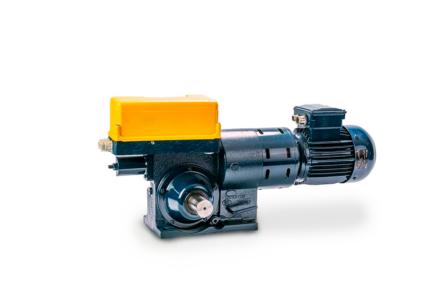

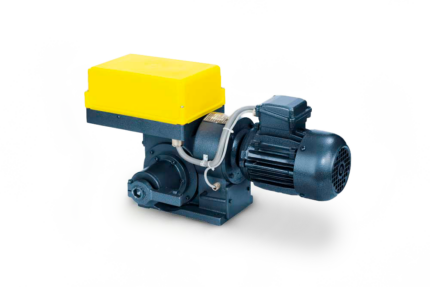

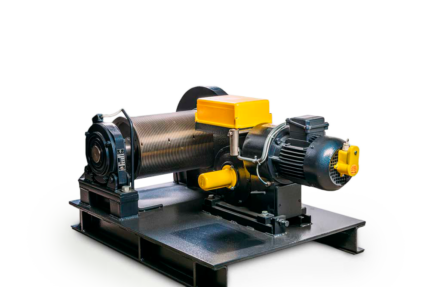

Discover the speed and efficiency of our Speedgate motor operator for high-speed doors! Our advanced technology makes opening high-speed doors effortless and fast, making your access control system even more effective.

- 230/400V

- Max torque: 300 – 500 – 700 Nm

- Speed 2.5 – 3.5 t/min

- Integrated absolute encoder

- Electromagnetic brake

- Intensive use

- Decoupling system possible

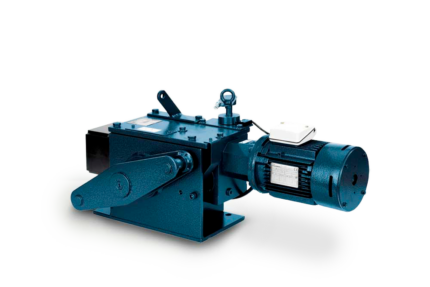

ROLLER DOORS

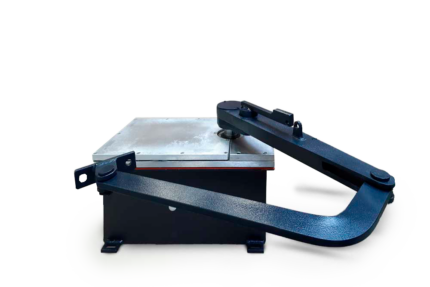

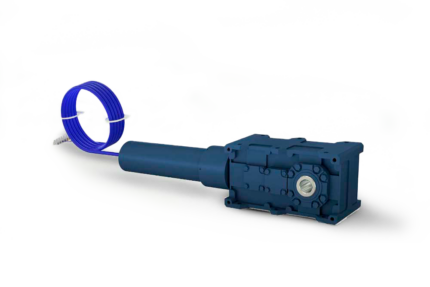

ROLLER DOORS ACCESSORIES

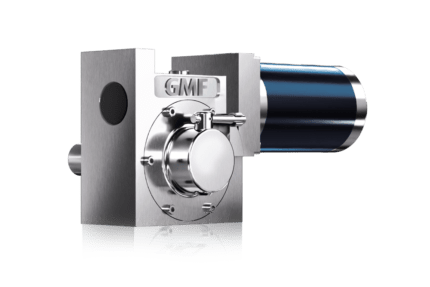

ACCESSORIES